The Behind Story of OPPO Find X5 Pro Birth

OPPO Find X5 series have revealed tech season’s most looked forward android smartphones. OPPO has managed to keep its head high with following its most popular Find X series. To make sure about the supreme quality in its newly introduced Find X5 Pro, high markups have been integrated by OPPO into this phone.

The construction of OPPO Find X5 Pro is interestingly built with multiple optimised processes. To put out the world-class quality, OPPO has surpassed every single set of the Find X5 Pro with the layers of these processes. This article is all about the inside of OPPO original making and how brilliantly the Find X5 Pro is assembled. We are going to look into the primary birth story of OPPO Find X5 Pro.

What goes inside the Motherboard of X5 Pro?

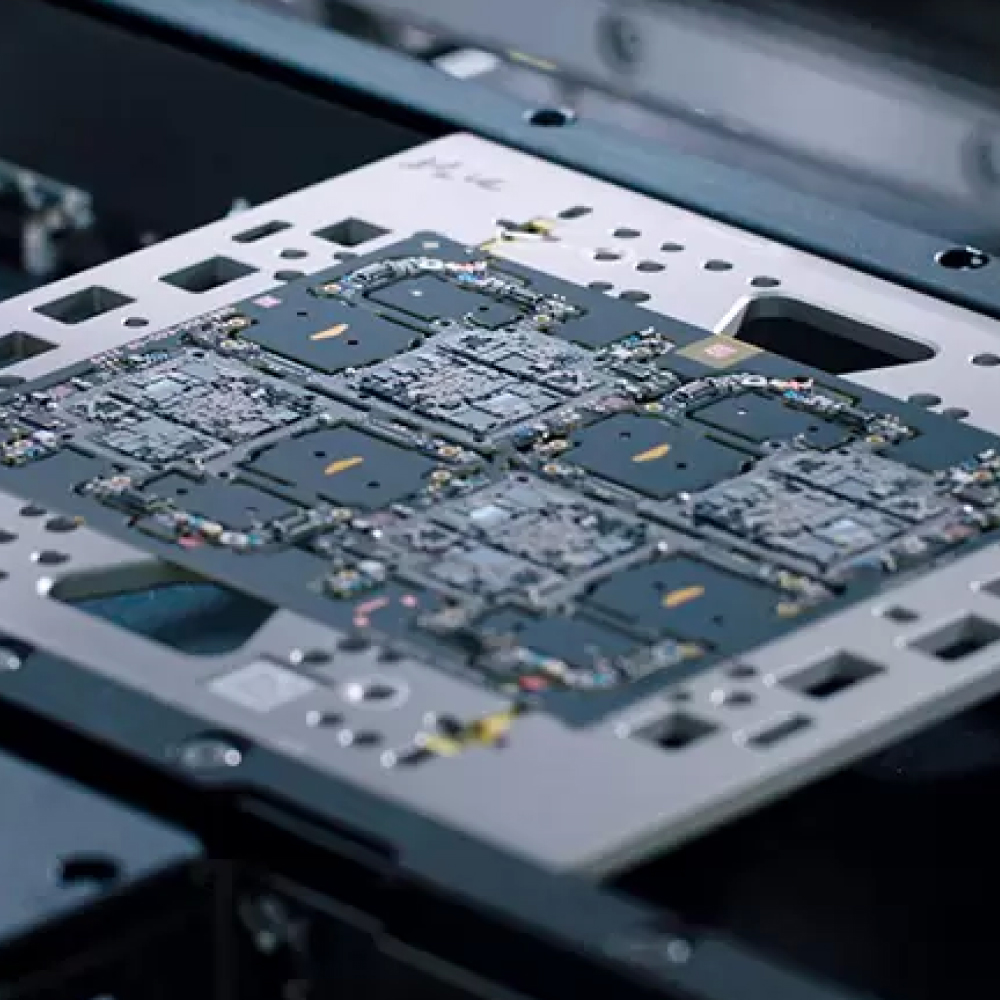

The first development in the OPPO’s factory for Find X5 Pro begins with its motherboard structure. The phone is embedded with small metal paths that combine all the components of the phone together. These paths are integrated with the ultra-fine quality labyrinth layout. The whole infrastructure is based on human’s brain to create an evolutionary mobile device.

Each component on the motherboard is wrapped in a road-like map. The motherboard consists of these roads that are printed on it through the robotic printers. These printers are capable of printing thousands of boards in one month of duration. Components such as CPU are mounted on the boards with extreme level of accuracy that is almost impossible with any human hand. If you come to measure the smallest component integrated onto the motherboard, it is around 0.4mm by 0.2mm. On a single chip mounter, more than 400,000 can be placed within an hour.

To find and evaluate any possible errors during the process, OPPO uses Auto optical Inspector camera. This camera is responsible for checking any issues in the pathway. As the components are each customizable designed and depicted carefully, the auto inspector looks up for even the slightest deviation. If the blueprint has a minor difference, the optical camera notices it first-hand with its programmed function.

On the OPPO Find X5 Pro board, the rigid conductive map takes place after it is baked for melting the metal powder. During this process, every step is carefully handled to control the temperature and humidity of factory floor. The final chip and line of solder are transformed into this rigid map, in actual. The quality of the solder is also tested after every two hours through X-ray testing. A machine called solder paste inspection is used for reviewing each board.

The whole testing process is 90% automated. The production experts from OPPO need to majorly get into the first indications of any possible issues. As thousands of phones need to be produced and sold over multiple countries, the testing precision is kept crucial. OPPO makes sure to contribute utmost efficiency in every process for the highest level of accuracy.

Find X5 Pro Camera Quality Test

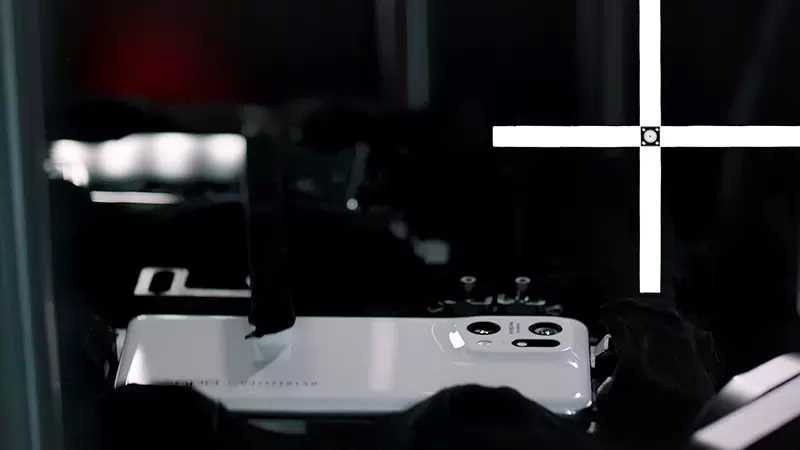

The new Find X5 Camera comes with revolutionary features like 5-axis camera stabilization. These brand-new technology inclusions need to be ensured for their quality standards. An OIS test is conducted at OPPO factory that passes each camera through examination. This test is basically held for checking the image stability of the lens and sensor. The camera is tested for delivering the ultimate peak performance and its functioning ability.

A machine set is used to mount the OPPO Find X5 Pro that provides a three-degrees and 6Hz frequency jitter angle. In every second, the machine sways in the back-and-forth direction up to six times with 3°. This is done to replicate a similar human hand shaking while shooting videos and photos. The testing also includes a rolling motion of 0.7° that is applied for the 5-axis system. Alongside the traditional OIS test, the sensor-shift angles and rotation are also tested separately. This test is actually the first in the tech industry and leads to a better sensor optical stabilization.

The tests are also taken through the shutter speed of 167ms. This speed is same as of the vibration to ensure the images still appear sharp instead of blurry or fuzzy.

The QE Reliability Lab of OPPO

OPPO’s most intensive phone testing takes place at its lab called QE Reliability lab. So, the OPPO Find X5 Pro is gone through the rigorous testing process in this lab. Every phone is tested individually to pour out any defective pieces or errors on the manufacturing side. Basically, this also includes tortured testing in a short span of time to validate the smartphone can through the most in normal years of use.

Firstly, the phone is checked to pass the meticulous OPPO phone standards. A total over 150 tests are conducted over the phone to make sure it goes through real-word concerns and pressures. The phone is tested through dropping it from a one-meter height 300 times on to the hard surface. Similarly, a casual drop of 1-to-1.5-meter distanced surface is also practiced. This is done to check the typical free-falling of smartphones that can take place anytime.

Other drop test of this OPPO phone includes it to drop from 10 centimeters of height for almost 28,0000 times. These drop-tests are conducted to make sure of the quality of the Find X5 Pro’s design. While some of the weakly designed phone structure can’t handle these kinds of drop, X5 Pro is made to do it.

The design of the OPPO Find X5 Pro is wrapped with ceramic casing with 1000° C calcination. This casing is assembled with the utmost strength and quality to make sure to go through hundreds of tests. It all associates to the quality standards of OPPO and longest durability of its smartphone. Surely made to last, the Find X5 Pro is strived through rigorous tests for solid longevity.

The hot and cold temperature testing of the Find X5 Pro is also conducted for further assessment. Each phone is kept at a minus freezing temperature of 40 degrees for the extreme cold conditions. Other test is by keeping it through 75 centigrade high temperature for analysing the hottest temperature it can take. The phone also goes through water testing with 1.5m depth and 30 minutes of hold.

Vast 5G Frequency Bands

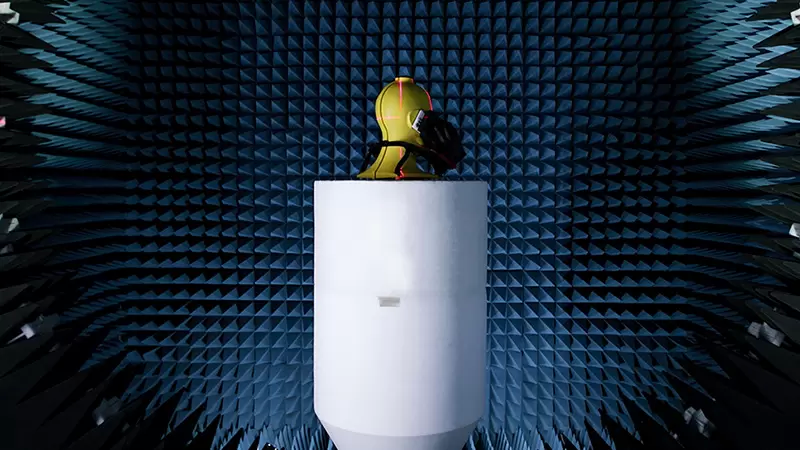

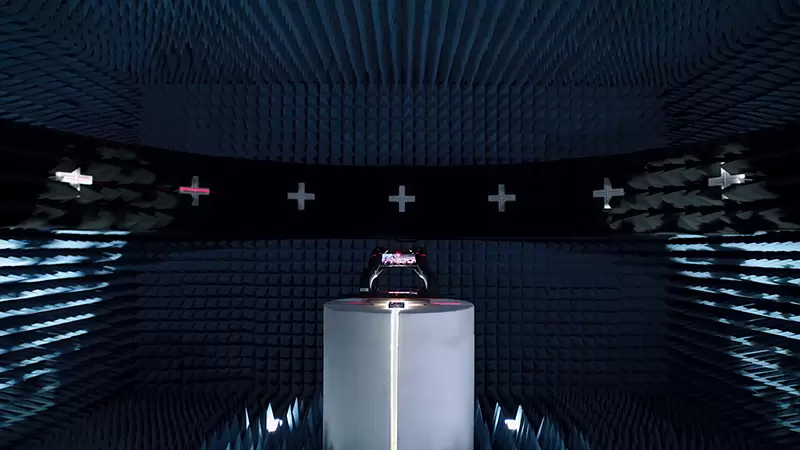

OPPO Find X5 Pro is also made sure to equip the widest range of 5G bands. To maintain the 5G support around the world for maximum connectivity, the phone is able to cater millions of world users. Another lab of OPPO known as the OTA lab contains signal generators for testing the mobile antennas. These tests evaluate the effectivity and signal strength for all kinds of use case scenarios. The 5G smartphone is also tested in landscape and portrait directions to cross check connectivity strength.

The antenna used inside OPPO Find X5 Pro is designed carefully for getting the best user experience. This helps for the best overall experience during phone calls, video watching and gaming. When the phone has lower latency in the middle of videos or gaming, the phone still meets the best 5G connectivity standards.

The OPPO Find X5 Pro is set to carry bumps and knocks without any blatant damages. Its withstanding power leads to being drenched, freezing, accidental and situational dropping and soaking sweat conditions. Other features of the phone such as fingerprint scanners, buttons and sockets of the phone are also tested for over ten thousand times.

Bottom Line

OPPO Find X5 Pro meets all industry standards, in fact elevate the quality to the next level durability. The aspirant engineering of this OPPO android smartphone is successfully held upon millions of tests. This also extravagates the manufacturing standards of the phone to ensure more than average years of use.